Conductors

A conductor is the core component that allows the flow of electrical current in one or more directions. A metal wire is a common electrical conductor.

After over 80 years in the business, we’re experts in finding the perfect combination of cable materials and components to create the best solution for you. Explore the key components and common material choices below.

There any many cable materials and components to choose from when it comes to designing and manufacturing cable solutions. At Habia, our innovative research and development teams have extensive knowledge and experience when it comes to material science and the electrical engineering of cables and harnesses.

Whether it’s selecting the best metals and strandings to use as a high-performance conductor, or finding the right polymer insulation to meet challenges like extreme heat or radiation, our cable design experts will lead you in the right direction. We have a deep understanding of the properties and functionality required to meet a customer’s needs – and how to select or create the specific cable materials and components necessary to bring those properties to life.

Learn more about some of the components and material types used in cables and harnesses by browsing the categories below.

A conductor is the core component that allows the flow of electrical current in one or more directions. A metal wire is a common electrical conductor.

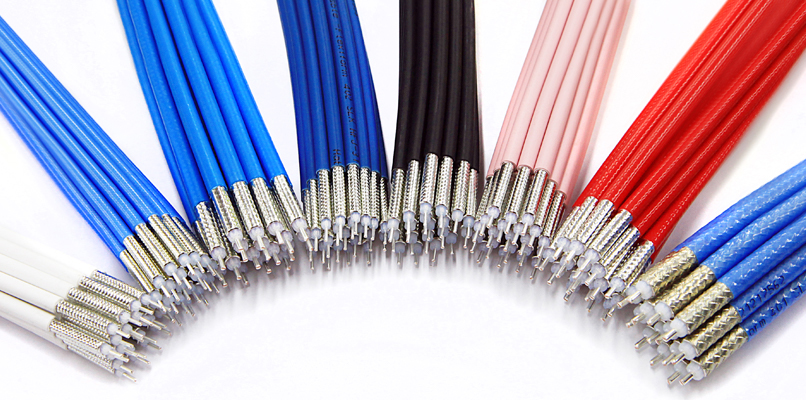

Insulation and sheath are the plastic components of a cable that protect the conductor. The insulation isolates the flow of electricity, and the sheath wraps around the outside of the cable to protect the conductors inside and enable electricity transmission.

A shield, or screen, is a metallic layer placed over one or more insulated conductors to either protect them from, or prevent them causing electrical interference.

Tapes, or binders, and fillers are applied to improve flexibility or roundness of the cable, to protect the insulation or sheath, or to ease production.

If you’re looking for a high-temperature material combined with strong electrical resistance and mechanical properties, PTFE is usually the go-to choice.

PEEK is a very versatile material and as a result, can be found in many demanding environments, including nuclear power plants, military shipboards and vehicle exhaust sensors.