BFOU and RFOU cables

Our cables are made in full compliance with the NEK TS 606 standard and approved by DNV, amongs others.

At Habia, we have an extensive range of standard products, including industry-standard wires and cables, cables made to third party specifications, and proven cable concepts that we’ve developed over the years. All of them can be adapted to meet your specific needs, no matter how unique.

Our cables are made in full compliance with the NEK TS 606 standard and approved by DNV, amongs others.

Our standard coaxial range includes RG, low-noise and sub-miniature coaxial cables – each with their own unique benefits and properties.

Cables made to our RTFRO™ concept. Includes multicores, multi-pairs and multi-triples.

Our Harnbraid™ over-shielding solution is ideal for harnesses.

The Habiaflame™ product range consists of fire resistant and flame retardant cables and wires, that can operate in 1565°C.

A wide range of different applications requires cable solutions with extremely small bending radiuses and a highly efficient cable setup.

Operating at frequencies up to 18 GHz, where high performance and flexibility are required, our Flexiform™ is the ideal solution.

Ideal for hybrid electric drives, our Hi-Flex™ cable range supports both military and commercial applications.

For applications exposed to temperatures from 150 °C upwards, Habia/HEW develops and manufactures high-temperature resistant cables that are used in demanding environments.

Habia offers a wide range of heating cables, heating lines and pipe trace heating systems for a wide variety of applications.

Whether for data transmission, energy supply, signal transmission, or as a hybrid cable with combined functions, ultra-flexible cables are used wherever moving appliances are connected and/or there is only limited space available for installation.

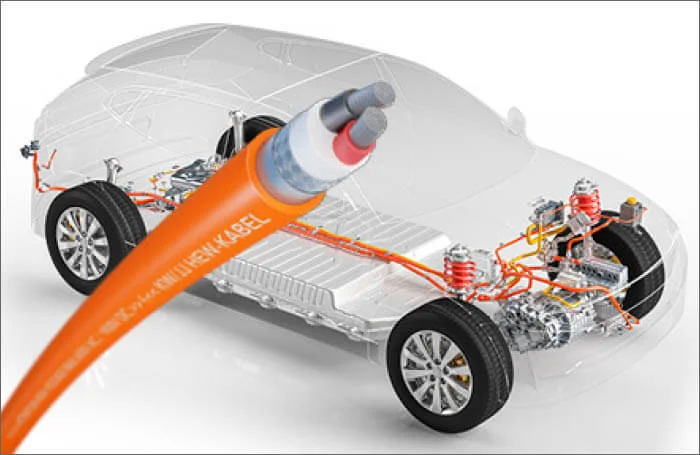

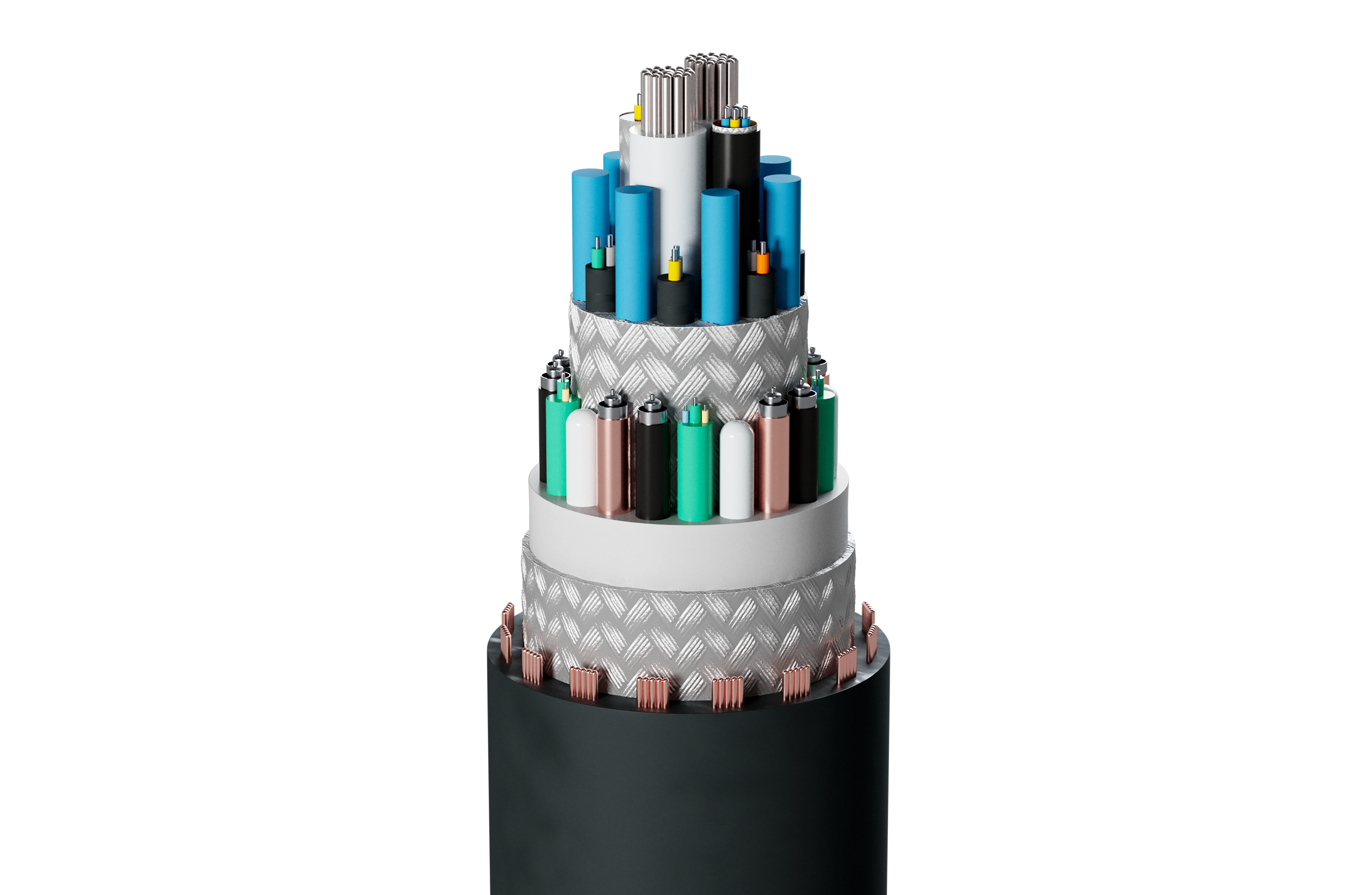

As a leading expert on technology and innovation for automotive manufacturers and system suppliers, we specializes in the development and manufacture of high voltage cables for electric mobility.

Instead of handling different individual cables, our hybrid cables enable multifunctional combinations of different types of cables under a common sheath.

Halogen-free cables made to our DMFRO™ concept, ideal for cost-effective marine applications.

We develop and manufacture numerous specialty cables for medical devices and instruments for a variety of applications, mainly in the fields of diagnostics, surgery and patient monitoring.

Whether in air, on land, or in the sea, our military cables are designed for maximum performance regardless of the physical, thermal and chemical conditions they may face. Our military-grade products meet some of the toughest specifications in the world.

We develope and produces application-specific miniature cables with cross-sections up to AWG56 (ø ≈ 0.0125 mm) as well as micro-coaxial cables up to AWG46 (ø ≈ 0.0399 mm).

Our high specification materials enable the Habiatron™ range of wires, cables and coaxial cables to operate in the extreme pressures, temperatures and radiation experienced in the safety-critical environments found in a nuclear power plant.

Operating at frequencies up to 18 GHz, where high performance and flexibility are required, our Flexiform™ is the ideal solution.

Habiasense™ - our cable range specifically made for measurement equipment.

Small multicores with ETFE, FEP, PTFE or HFI insulations and sheaths, made to standards.

A wide range of materials are available for use as wire insulation; ETFE, FEP, PFA and PTFE.

Habiatherm™ - our cable range specifically made for temperature sensors.

All our certified UL AWM styles; single cores, twisted wires, multicore cables and coaxes.

Zeroarc® is a ground-breaking insulation system that allows us to create compact, medium to high voltage cable solutions.